Solar installation for a client working from home

The client is tech-savvy and runs an IT business, with two other members of the family also working from home. Before the solar installation, two portable 1kVA inverters took care of the network installation of the home, which includes an incoming fibre connection, routers, switches, security cameras, and computing equipment in three office spaces, occupied during office hours and beyond. Eventually though, in case of a prolonged power cut, these inverters will run out of steam as well. While they managed to run for 16 hours during a recent 36 hour blackout, what was needed was an installation that would allow the offices, as well as the rest of the home, to run unaffected by loadshedding or power failures.

Clever segmentation of power requirements throughout the home means that non-essential items such as the swimming pool, stove, and geyser do not draw power from the batteries that could otherwise drain the system. As the client learns to manage the system, these items can be included, eventually reducing the monthly electricity bill.

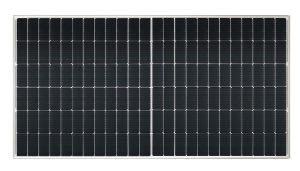

The solution was a 5kVA Sunsynk inverter, three 5kVA Volta Stage 1 batteries, and nine 450W half-cell mono crystalline solar panels. The equipment is installed in an area as far away as possible from the main home, in the corner of a double garage. There is little fire hazard in this area, and sufficient ventilation. The panels are installed on a high, north-facing roof with no shade interference at all, maximising their total daily exposure to the sun. In addition, the panels are not visible from the street, reducing the risk of theft.

The original two portable inverters remain part of the solution for the moment. They are located in areas of the offices where they are out of the way.

Installation

From the start, this project was delivered to perfection. Having examined other installations Ohmtek had completed in the area, the owner was more than happy that they would be a cut above the rest. Once the quotation was received, it was clear that of three quotations obtained, this was the one to go for. Everything was properly specified, with no guessing needed. In addition, a CoC was included as part of the installation.

Once the deposit was paid, the wait started for the most important items – the inverter, three batteries, and nine panels. Due to high demand, it took about three weeks, but once the inverter was delivered, the batteries and panels followed within a few days. The exact positioning of the major items was discussed, and once a way was found to route the panel cabling to the inverter, the job started quickly.

One part of the extremely efficient team installed the panels within a day, while the rest of the team took care of the routing of cabling from the roof to the inverter, as well as to the distribution board (DB), about three rooms away. By the end of the second day the DB had been split into an essential and non-essential section, geyser manager installed and configured, and the prepaid meter moved to fit in with the layout of the rest of the items. The owner was most impressed with the minute detail in routing cabling between the inverter, batteries, AC, and DC units. Every cable, where there is more than one in a group, follows exactly the same radius in bends, and thus they look identical. The same goes for cabling inside the AC and DC units, which you will never see. The attention to detail was evident.

Day three saw the linking of the batteries, final cabling completed, and the first powering up of the unit. Since it was a beautiful autumn day, the sun was shining brightly and in no time the batteries started charging. The Volta Stage 1 batteries looked impressive with their four LEDs. Final touches were made, including proper labelling that is required before a CoC can be issued. At the same time, the Sunsynk app was downloaded and configured to learn how to monitor and manage the system.

The system was allowed to run for a few days to test it for any possible malfunction. Tweaking took place – configuring the geyser's management system; deciding which power-hungry appliances could be run simultaneously; and where power could be utilised more efficiently. The effectiveness of the nine panels was tested over a few days, monitoring how early they started producing power, and when they produced no more at sunset.

The final phase of the project was to properly label the system, an essential part of the work before a certificate of compliance can be issued. It was an interesting experience, which the owner witnessed as the installer completed the process.

After the final checks were done, the certificate of compliance was issued. This vital document was immediately scanned, and the original put in the safe for safekeeping. What remains is to indicate the new system to the insurance company.

Having read and heard horror stories of installations going south, the owner was immensely impressed with the Ohmtek team's attention to detail. It was a pleasure to pay the balance and congratulate the business on a job well done. They are highly recommended.

What to do next

It is not a matter of whether the national electricity grid will collapse. It is simply a matter of when. Do not let this happen to you. Protect yourself, your family, and your home against the chaos this will result in.

Call us today